The Company

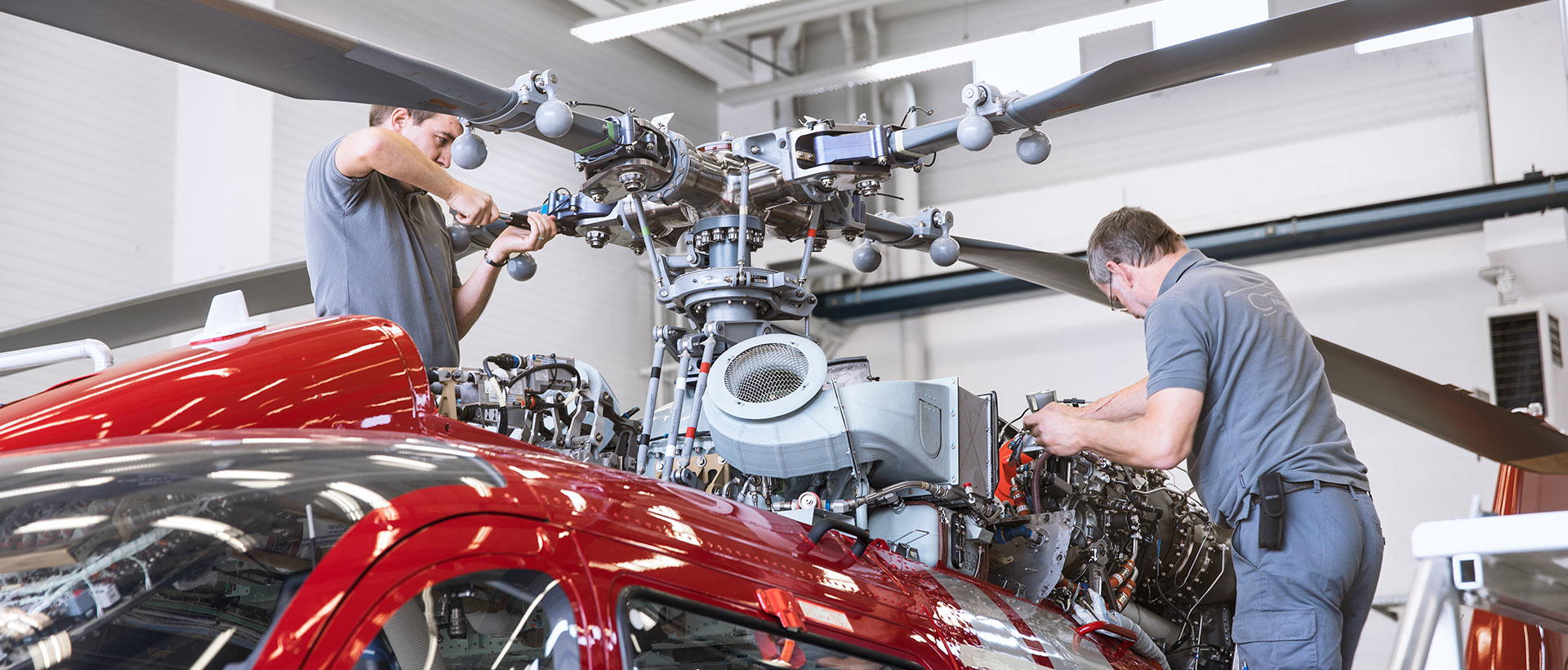

Intercopter GmbH is an EASA approved Part 145 maintenance organisation for rotary and fixed wing aircraft under the approval number DE.145.0126.

Services

Maintenance and repair, production (part 21G), component maintenance, retrofitting, spare part supply for rotary and fixed wing aircraft

Locations

Base maintenance in Taufkirchen/Ottobrunn near Munich and Emden; Line maintenance in Borkum, Helgoland, and Norden-Norddeich; Fixed wing line maintenance in Oberpfaffenhofen and base maintenance at the Airport Memmingen

Services

Intercopter offers a wide range of maintenance service for a variety of helicopter types manufactured by Airbus Helicopters, Bell Helicopters, and Leonardo Helicopters:

- Agusta A109 E/S AW109SP (EASA.R.005)

- Airbus Helicopters AS 350 Series / H130 (EASA.R.008)

- Airbus Helicopters AS 355 N/ NP (EASA.R.146)

- Airbus Helicopters BK 117 C1/C2/D2 (EASA.R.010)

- Airbus Helicopters BO 105 A/C/D/S (EASA.R.011)

- Airbus Helicopters EC 120B (EASA.R.508)

- Airbus Helicopters EC 135 Series (EASA.R.009)

- Airbus Helicopters EC 155 (EASA.R.105)

- Bell Helicopter Textron Canada 206 Series (EASA.IM.R.512)

- Bell Helicopter Textron Canada 407 (EASA.IM.R.512)

Component maintenance and spare part supply complete the service range offered to our customers. Furthermore, we possess a large collection of special tools and modern boroscope equipment, which is used among others for engine inspections.

Intercopter is also an approved EASA Part 21G Production Organisation.

- All inspections required by the manufacturer or the authority

- Airframe, engine, and equipment repair

- Interior panelling repair

- Minor and major changes according to STCs, SBs, and current manufacturer documents

- Troubleshooting

- Installation of mission equipment

- Partial or complete paint job by one of our subcontractors

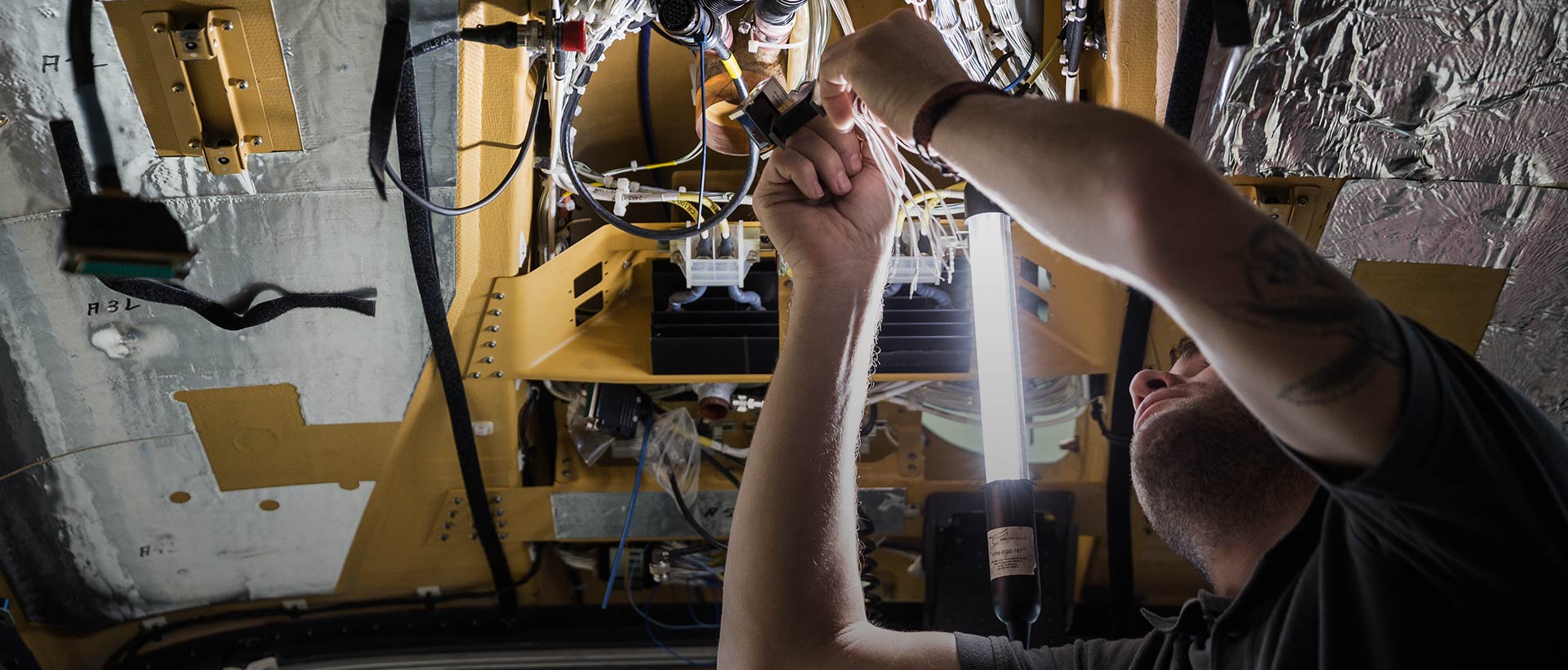

- Avionics check according to the approved maintenance programme

- Engine maintenance:

- Allison / Rolls Royce 250 series, limited to maintenance including module change

- Pratt & Whitney (PW 206 & 207 series, limited to maintenance)

- Turbomeca (ARRIUS 1 & 2 series, ARRIEL 1 & 2 series)

- C1/C2 Appliances/Parts

- DC Power Distribution System

- Cabin Equipment/Furnishings

- Equipment/Furnishing System Wiring

- Battery maintenance (nickel-cadmium) by the manufacturers Hawker/Varta, Marathon, and SAFT

- Emergency floats maintenance for AS350, AS355, and EC135

- Main rotor head BO105/BK117 series

- Retrofitting/modification in cooperation with Part 21J

- Annual avionics check according to Capability List

With our many years of experience, we can also offer you our support in purchasing new or used helicopters.

We carry out detailed pre-purchase inspections including the aircraft documentation for the listed helicopter types.

- Boroscope inspections

- Spare part trade

- Balancing

- Weighing

- Oil inspections

- Ultrasonic cleaning of parts

- Leak testing of fuel system

- Interior and exterior cleaning

- Special tool rental

- Metal works

- Pitot-static testing

The Company

Milestones

2003

- Intercopter GmbH launch in Ottensoos near Nuremberg

2010

- Relocation to Taufkirchen near Munich

2012

- Launch of fixed-wing maintenance (additional locations: Airfield Oberpfaffenhofen, Munich Airport)

2013

- Startup operations at the Emden base

- Launch of the avionics maintenance centre

- ZODIAC authorised repair station

2014

- Relocation to new hangars in Taufkirchen

2015

- Extension to Bell 206/207 series

2016

- Extension to H145 (BK117 D2) series

- Startup operations at the line stations in Borkum and Helgoland

2017

- Startup operations at the line station in Norden-Norddeich

2018

- Extension to H130

- Startup operations at the line station Memmingerberg

2019

- Approval as EASA Part 21G Production Organisation

- Extension to Base Maintenance Memmingerberg

- Extension to EC155

- Start as a training company for aircraft mechanics

Persons of Contact

Locations

Main site in Taufkirchen

The main site for base maintenance in Taufkirchen near Munich on the Airbus Group premises has been operated by Intercopter GmbH since 2010. On an area of 1,500 m² with an additional workshop area of 400 m², 80 m² storage space, and an office area of 100 m², we perform helicopter maintenance for our customers. The hangar is equipped with a crane, air-conditioning, and the base has its own helicopter landing site.

The site is also of historical importance: The maiden flight of the BO105 took place here, as well as the development and testing of established helicopter types such as Tiger, NH90, etc.

- Approx. 1,500 m² maintenance area

- 100 m² office space, 400 m² workshop space

- Crane (Capacity: 7 tonnes)

- Air-conditioning

- Own helipad

Emden base

In relation with the offshore operations, Intercopter GmbH has established another base maintenance site in Emden. Line maintenance has been performed in Emden since 2009. In 2016, the site has been extended to also serve as a base maintenance site.

- 625 m² maintenance area

- Additional storage space and quarantine storage

- Additional workshops

- Mobile crane

- Connected to the apron of the Emden airfield

Line stations

Additional line stations are operated in:

- Helgoland

- Norden-Norddeich

- France St. Nazaire

Contact Us

Headquarters and shipping address

Airbus Group premises, Building 85.1

Willy-Messerschmitt-Strasse 1

82024 Taufkirchen

Phone: +49 (0)89 / 649 555 0 – 700

Fax: +49 (0)89 / 649 555 0 – 791

office@intercopter.de

Emden base

Airfield Emden

Gorch-Fock-Strasse 107

26721 Emden